Heavy-duty truck collisions are often caused by neglected brake maintenance or substandard parts, leading to increased stopping distances and sudden braking failures. To prevent these accidents, regular inspections, timely component replacements, advanced diagnostics, driver training, and robust fleet management protocols are essential. Investing in specialized collision centers for auto body restoration further enhances safety by minimizing downtime, ensuring critical systems' integrity for future use.

Brake failure can have catastrophic consequences, especially in the high-stakes world of heavy-duty trucks. This article delves into the mechanics behind these failures and their role in causing collisions. We begin by demystifying the complex brake systems common in such vehicles, then identify key factors contributing to failure. Furthermore, we explore proactive safety measures and strategies to mitigate risks, offering vital insights for fleet managers and drivers aiming to prevent heavy-duty truck collisions.

- Understanding Brake System Basics in Heavy-Duty Trucks

- Common Causes of Brake Failure Leading to Collisions

- Mitigating Risks and Enhancing Safety Measures for Prevention

Understanding Brake System Basics in Heavy-Duty Trucks

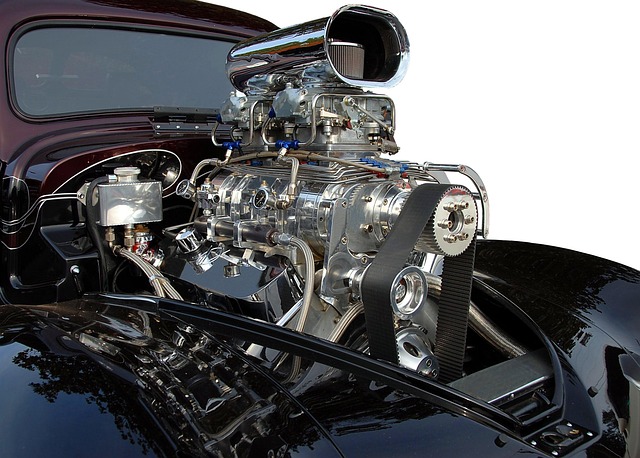

The brake system in a heavy-duty truck is a complex network designed to bring immense weight to a stop safely and efficiently. At its core are components like disc brakes, drum brakes, calipers, pads, and rotors—all working together to convert the driver’s input into frictional force, slowing or stopping the vehicle. Understanding these basics is crucial when considering how brake failure can lead to a heavy-duty truck collision.

Regular maintenance plays a vital role in keeping this system effective. Pads and rotors wear down over time, requiring periodic replacement to ensure optimal braking power. Ignoring maintenance or using subpar parts can compromise the integrity of the entire system, increasing the risk of sudden brake failure—a scenario that can have severe consequences on the road, particularly at high speeds or with heavy loads. Moreover, understanding Mercedes Benz repair principles (as an example of a premium heavy-duty truck brand) can help drivers and fleet managers appreciate the importance of specialized care for these sophisticated systems, thereby enhancing safety and preventing collisions.

Common Causes of Brake Failure Leading to Collisions

Brake failure, a critical issue in heavy-duty trucking, can stem from various causes, often leading to collisions on the road. One of the most common culprits is worn-out or improperly maintained brake pads and rotors. Over time, intense braking actions during long hauls or steep descents can cause these components to degrade, reducing their effectiveness. This wear and tear can result in increased stopping distances, a significant concern when navigating high-speed transportation corridors.

Additionally, fluid leaks within the brake system pose another critical risk. Brake fluid is essential for transmitting pressure to the brakes’ mechanical parts. Leaks due to worn seals or damaged lines can lead to fluid loss, compromising the braking power. When drivers fail to address these issues promptly, it may result in sudden and unexpected braking failures, potentially causing collisions and severe car damage repair. Auto body restoration becomes a necessary step after such accidents, ensuring that the truck’s critical systems are not just operational but also safe for future use on the road.

Mitigating Risks and Enhancing Safety Measures for Prevention

Preventing heavy-duty truck collisions due to brake failure requires a multi-faceted approach. Regular maintenance is paramount, encompassing meticulous inspections and prompt replacement of worn components. Advanced diagnostic tools can identify potential issues before they escalate, allowing for proactive measures. Additionally, driver training programs emphasizing safe braking techniques and emergency maneuvers are crucial.

Implementing robust safety protocols in fleet management further mitigates risks. This includes enforcing strict vehicle inspection schedules, ensuring proper fluid levels and tire condition, and promoting a culture of safety awareness among drivers. Moreover, investing in collision centers equipped with specialized tools for frame straightening and fender repair can facilitate swift and effective repairs, minimizing downtime and enhancing road safety.

Brake failure can have devastating consequences, especially in heavy-duty trucks. By understanding the basic brake system, identifying common causes of failure, and implementing enhanced safety measures, we can significantly reduce the risk of these collisions. Mitigating risks through regular maintenance, driver training, and modern technology is essential to ensuring safer roads for everyone.